Flexible Intermediate Bulk Container (FIBC) or jumbo bag

Flexible Intermediate Bulk Containers also commonly referred to as FIBC Bags or bulk bags are a type of packaging that is suitable for the transportation and storage of many products. We Exportish International, stand strong as fibc bags supplier as we supply premium quality FIBC Bags that are made with precision. Our FIBC Bags are designed using the most modern tools and best-quality input materials to guarantee their durability. Whether it is for agricultural products, chemicals, minerals or any other industrial use, we have the FIBC Bags to meet your needs.

Specifications

| Technical Data | Description |

|---|---|

| Material | Recycled (20% or 30% Rpp) or 100%Virgin PP, laminated or unlaminated, ventilated, conductive type C, dissipative type D, vento, flame retardant |

| Construction | U-shape, flat 4 panels, double wall, bag in bag, tubular, 1Looper, 2Looper, Italo type |

| Inlet | Open top, top skirt, top spout, conical top |

| Outlet | Flat bottom, bottom spout, bottom skirt, full star bottom, conical |

| Safety Factor | 5:1, 6:1, 8:1 |

| Safe Working Load | From 100 kg to 2500 kg |

| UV Resistant | Yes |

| Document Pouch | A4, A3, A5 or customizable |

| Product Height | Fully customizable |

| Fabric Color | Any color, most common color white |

Introduction - Flexible Intermediate Bulk Container

A Flexible Intermediate Bulk Container (FIBC) is a large, flexible bag designed to transport and store bulk quantities of dry or granular materials. These materials can range from powders, granules, and flakes to minerals, chemicals, and food products. FIBCs are an efficient alternative to traditional rigid containers and offer numerous benefits such as ease of handling, reduced storage space, and cost-effectiveness.

In the world of industrial packaging, efficiency and versatility are paramount. One solution that has gained immense popularity in recent years is the Flexible Intermediate Bulk Container, commonly known as FIBC or bulk bag. The FIBC industry has revolutionized the way materials are stored, transported, and handled across various industries. In this comprehensive guide, we will delve into what flexible intermediate bulk container bags are, the materials they’re made of, and the different types available to cater to diverse needs.

Flexible Intermediate Bulk Containers manufacturers are companies that specialize in providing packaging solutions and materials for industrial purposes. These suppliers offer a wide range of products, like industrial bulk bags and services tailored to meet the packaging needs of different industries. Flexible Intermediate Bulk Containers manufacturers are experts in their field and can provide the perfect solution to each transportation or storage challenge.

Materials Used in FIBCs

FIBC Containers are typically made from woven polypropylene (PP), a strong and durable synthetic plastic material. Polypropylene is renowned for its resistance to moisture, chemicals, and UV radiation, making it suitable for a wide range of applications. The woven structure provides structural integrity and prevents tearing, ensuring the bag’s reliability during transportation and storage.

Manufacturers of industrial bulk bags often provide customization options to meet specific requirements. This can include tailoring bags to fit certain dimensions, incorporating specialized safety features, and adhering to the fibc industry specific regulations. Customization ensures that the packaging precisely fits the material being transported, optimizing safety and efficiency. To have access to such options, selecting the right flexible intermediate bulk containers manufacturers is also crucial.

Understanding the Different Types of FIBC Bags and Their Applications

FIBCs come in various types, each tailored to meet specific requirements based on the material being transported, the environment, and handling processes. Custom container packaging is also available at some flexible intermediate bulk containers manufacturers, and is highly customizable to unique needs.

Some common types of FIBCs, Type A FIBCs (Conductive), Type B FIBCs (Antistatic), Type C FIBCs (Conductive), Type D FIBCs (Static Protective).

Type A FIBC Bags (no electrostatic protection)

Type A FIBCs provide no static protection. Made of woven polypropylene (woven pp), static electricity is generated as materials rub against the inside surface of the bag as they are filled and emptied. Since there is no static protection provided by Type A bags, it is essential that they are not used to store or transport combustible materials, or used in flammable or combustible environments.

Type B FIBC Bags (Surface breakdown voltage of - 6kV)

Like Type A bulk bags, Type B bulk bags do not have any mechanism for dissipating static electricity. The difference is that Type B bulk bags are made from materials that have a low breakdown voltage to prevent the occurrence of highly energetic, and dangerous propagating brush discharges (PBD). Although Type B FIBCs can prevent PBD, they cannot be considered antistatic FIBC because they do not dissipate electrostatic charge. Normal brush discharges can still occur, which can ignite flammable solvent vapors.

Type C FIBC Bags (Electrically conductive or groundable)

Are also known as conductive or groundable FIBC. Originally they were made from entirely conductive materials. Groundable Type C FIBCs are more commonly made from non-conductive polypropylene interwoven with conducting yarns, normally in a grid pattern. The interconnection of conductive yarns and the connection to ground or earth are critical to the safe use of Type C FIBC. As with any manual operation, ensuring interconnection and grounding of Type C FIBC is subject to human error.

Type D FIBC Bags (Crohmiq static dissipative or antistatic)

Anti static bulk bags are made from static protective fabric designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges, without the need for a connection from the bulk bag to ground or earth. Using CROHMIQ fabric to construct anti-static bulk bags eliminates the inherent risk of grounding failure that is always present whenever conductive Type C FIBCs (grounded FIBCs) are used.

What Does Flexible Intermediate Bulk Containers (FIBCs) Cover?

Flexible Intermediate Bulk Containers (FIBCs) have become indispensable in industries requiring the efficient transportation and storage of bulk materials. Their adaptability, cost-effectiveness, and sustainability have made them a staple choice for businesses worldwide. By understanding the materials used and the various types of FIBCs available, industries can make informed decisions when choosing the right packaging solution for their specific needs. Whether it’s chemicals, food products, minerals, or any other bulk material, flexible intermediate bulk container bags offer a reliable and flexible way to move goods from one point to another, ensuring convenience, safety, and efficiency.

-

Food-Grade FIBCs:These flexible intermediate bulk container bags are specially designed for transporting and storing food products. They adhere to strict hygiene and safety standards to prevent contamination and ensure the integrity of the food items.

-

UN Certified FIBCs:When transporting hazardous materials, FIBCs must meet the United Nations’ regulatory standards. UN-certified FIBCs are rigorously tested to ensure their compatibility with specific hazardous substances.

-

Baffle FIBCs:These flexible intermediate bulk container bags have internal baffles or panels that maintain the shape of the big bags even when it’s partially filled. This design prevents the material from shifting excessively during transportation, optimizing stability and safety.

-

4-Panel Bags:These square or rectangular-shaped bags consist of four fabric panels that are sewn together. They are perfect for storing and transporting bulky goods.

-

Circular Bags:The bags are crafted from a single piece of fabric that is transformed into a tube-like shape with a cylindrical form. Flat panels are stitched at the top and bottom to create a cylindrical structure for the bag.

-

Conical Bag:Conical bags are ideal for materials that can be difficult to discharge. Their conical shape helps ensure complete emptying of contents, minimizing residue and waste.

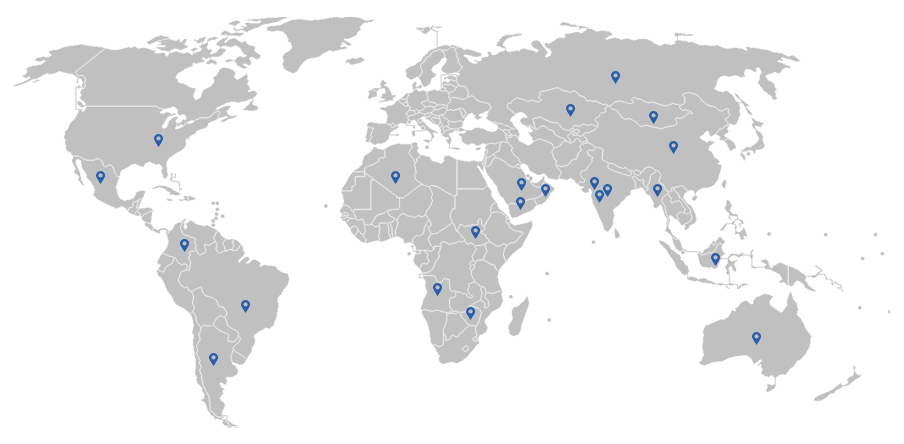

Global Customers

We serve clients across the globe, covering 42 Countries Across 7 Continents